Acoustic levitation

Single drop test

The use of spraying processes has many applications in the chemical and pharmaceutical industries, but also in food technology. In particular, the production of powders from suspensions is carried out by spray drying to produce everyday powdery products, such as baby food, powdered milk or soluble coffee. Parameters of the process, such as temperature, humidity or the droplet size produced are decisive for the quality of the product. Reactive spray drying processes are also highly relevant for the production of various metal salts, catalysts and polymers. Tracking a single droplet in a spray tower would require a disproportionate amount of equipment, but this is essential to understand how the process parameters affect the properties of the resulting product.

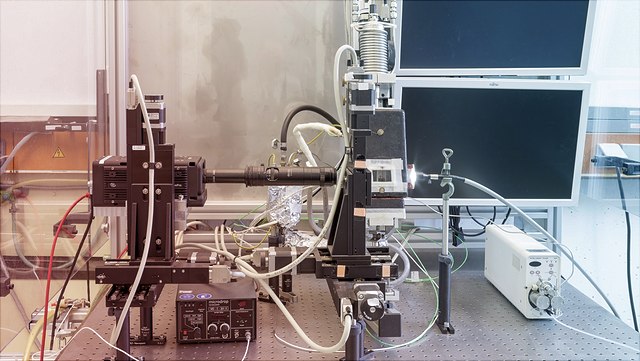

Droplets can be made to float by means of a standing ultrasonic wave. This technique, known as acoustic levitation, allows the examination of droplets with diameters of up to several millimeters without the influence of a carrier or vessel ("containerless processing"). The objective of the present project is the optimization of an existing acoustic levitator and the tracking of chemical reactions in the floating single droplet, for example by means of Raman spectroscopy or a CCD camera.