SFB 1615 „SMART Reactors“

SFB1615

The German Research Foundation (DFG) is funding the Collaborative Research Center (SFB) 1615 "SMART Reactors". The SFB is located in the Dean's Office of Process Engineering at Hamburg University of Technology. Basic research in the SFB will enable new technologies for intelligent reactors to be developed in the future.

In order to counteract climate change and create more resilient supply chains, it is essential to use renewable resources, for example from plant waste, instead of fossil fuels such as oil and gas. However, these fluctuate seasonally and regionally in their availability and quality. New processes and equipment (reactors) that can adapt flexibly to changing conditions are therefore needed to process them. To enable such adaptation, parameters such as pressure, temperature, concentration and flow of heterogeneous mixtures (multiphase flows) within the reactors must be continuously monitored locally with sensors and corrected immediately. The name "SMART Reactors" says it all: it stands for how resources are converted sustainably (Sustainable) into various products (Multipurpose) by optimizing the reaction conditions autonomously (Autonomous). This leads to more resilient processes, which are then more transferable.

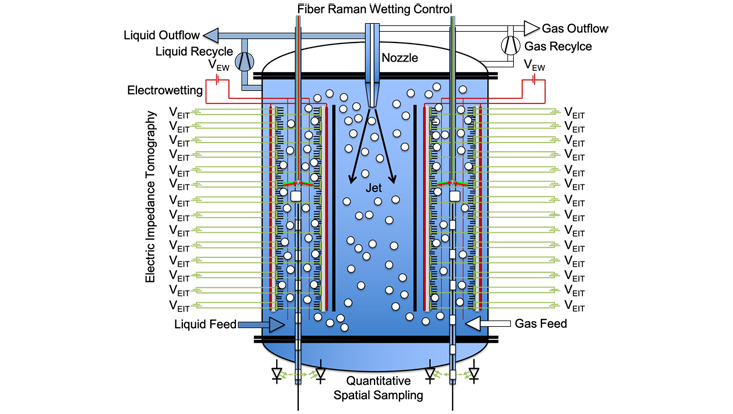

From the Department of Chemistry, Prof. Luinstra's working group is involved with one sub-project and Prof. Albert's working group with two sub-projects. For example, the development of novel, highly active and selective hydrogenation catalysts on chemically and electronically responsive carbon nanotubes (CNTs), which are grown and anchored on glass or metal structures and thus represent ideal structures for the chemical hydrogenolysis of glycerol to propanediols in a gas-liquid reaction phase, is being investigated. Another goal is the development of a prototype SMART multiphase reactor for the catalytic hydrogenolysis of glycerol (GL) to 1,2-propanediol (1,2-PD). This should enable real-time process control through the combination of 3D imaging by electrical impedance tomography (EIT), quantitative gas-liquid distribution measurements to calibrate the electrical impedance maps, internal control of catalyst reactivity by electrowetting and Raman measurements to investigate the wetting state of the catalyst.

Homepage of the "CRC 1615 - SMART Reactors for Future Process Engineering" at TUHH