Ba, Ma, Ph.D and jobs

Offers for student assistants

We are often looking for student assistants (SHKs), but at irregular intervals ….

You are welcome to ask at any time without commitment:

Dr. Werner Pauer

Room: TMC B 218

Phone: +49 40 42838-6007

e-mail: werner.pauer@uni-hamburg.de(pauer"AT"chemie.uni-hamburg.de)

Internships, bachelor, master and doctoral positions

Also in the future, beyond 2022, topics for all kinds of internships, bachelor or master theses or doctoral projects are available. Please contact:

Dr. Werner Pauer

Room: TMC B 218

Phone: +49 40 42838-6007

e-mail: werner.pauer@uni-hamburg.de(pauer"AT"chemie.uni-hamburg.de)

Analysis of polymer dispersions - Reverse engineering

Contact person: Werner Pauer

Email: werner.pauer"AT"uni-hamburg.de

Room: TMC B218

Tel.: 040 42838 -8991 6007

Duration: from 4-6 weeks

Designed for: research internship, bachelor's/master's thesis

Start: immediately!

The comprehensive processing takes place as part of a master's thesis

General description:

Reverse engineering involves analyzing and disassembling a product to understand how it works and then reproducing and/or improving it. The comprehensive analysis and characterization required for this is an interesting and demanding field of work. During the project you will get to know numerous analysis methods.

First, a terpolymer dispersion is examined with regard to monomer composition, molecular weight distribution, conformation, configuration, branching and particle size distribution. The identification of dispersion stabilization is also desirable. Potential analysis methods are mass spectroscopic methods, such as couplings from pyrolysis GC-MS, TGA-MS, NMR spectroscopy as well as IR and Raman spectroscopy. In addition to electron microscopy methods, dynamic light scattering (DLS) and chromatographic methods can be used to determine the particle size distribution.

After reverse engineering has been carried out, the dispersion must be synthesized and compared with the initial dispersion in terms of application properties, and the synthesis route must be adapted so that comparable application properties are obtained.

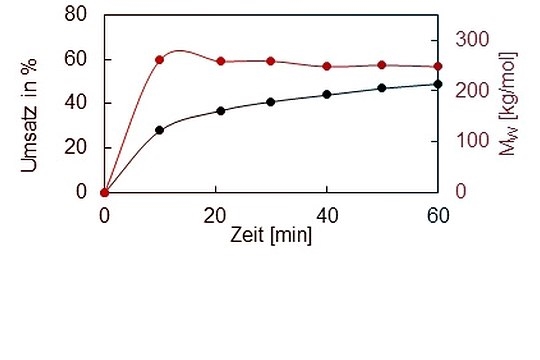

Transfer of a ring-opening polymerization of ε-caprolactone to spray polymerization in a spray tower

Contact person: Anne Frankowski/Werner Pauer

E-Mail: anne.frankowski"AT"uni-hamburg.de , werner.pauer"AT"uni-hamburg.de

Room: TMC C224 or B218

Tel.: 040 42838 -6054 oder -6007

Duration: 4-6 weeks

Designed for: Research internship in a Bachelor-/ Masterthesis

General description:

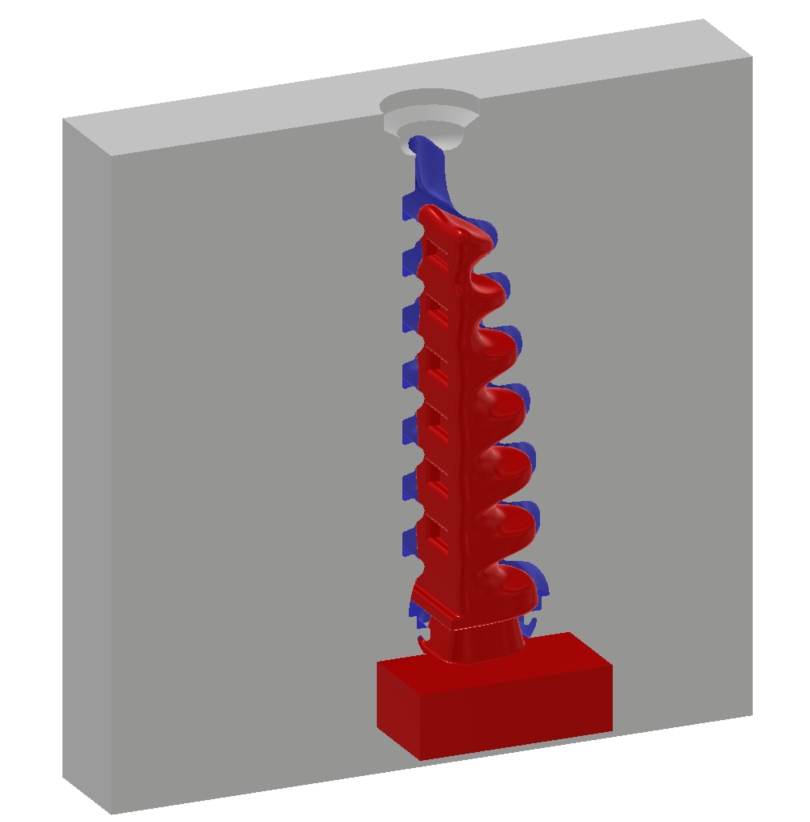

The ring-opening polymerization of ε-caprolactone is to be carried out in a single drop and then further developed for use as a spray polymerization. By optimizing test parameters such as temperature, concentrations, molar ratio between monomer and catalyst, etc., short reaction times and high molar masses should be achieved in order to investigate use in a spray tower and/or in a fluidized bed. The transfer of the reaction to the spray tower and the fluidized bed is also realized by means of modeling and 3D printing of various spray heads.

3d printed tools for Injection Moulding of Rubber Compounds

Contact person: Jens Chen, Werner Pauer

E-mail: i-chieh.chen"AT"uni-hamburg.de, werner.pauer"AT"uni-hamburg.de

Room: TMC A06 or B218

Phone: 040 42838 - 8245 or -6007

Duration: 4-6 weeks

Interpretation: Research internship in a Bachelor-/ Masterthesis

General description:

Injection molding of rubber compounds is a widely used technology in the manufacture of rubber and plastic products. The tools used in this process must be very precise to ensure the desired product quality and accuracy. However, manufacturing tools using traditional manufacturing methods such as CNC machining is very expensive and time consuming. 3D printing technology offers a promising alternative here, as it can produce prototypes and small series quickly and inexpensively.

The aim of this master thesis is to investigate the feasibility and suitability of 3D printed tools for the injection molding of rubber compounds.

The study is carried out in three steps. In the first step, different 3D printing technologies and materials are identified and evaluated. For this purpose, the advantages and disadvantages of each technology and each material as well as their suitability for the injection molding of rubber compounds are examined. In the second step, various 3D printed tool designs are created and manufactured. These tools are then evaluated using various tests such as dimensional accuracy, surface roughness and material compatibility. In the third step, the results from the first two steps are compared and evaluated to assess the advantages and disadvantages of 3D printed tools compared to traditional tools.

The results of this study will show whether 3D printed tools are suitable for the injection molding of rubber compounds. It is expected that 3D printed tools can be manufactured quickly and cheaply, and have comparable quality and accuracy to traditional tools. The conclusions of this study can help to promote the use of 3D printing technology in tooling for rubber compound injection molding and enable the development of new tooling designs.

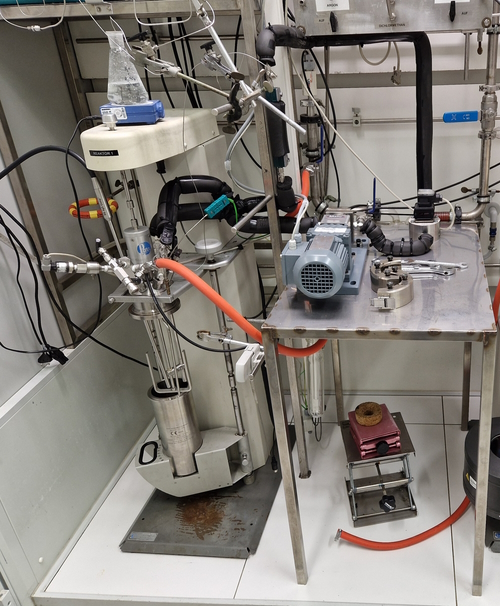

Experimental implementation of a scale up for emulsion copolymerisations using 3D-printed stirring elements

Contact person: Maria Klippert/Werner Pauer

E-Mail: maria.klippert@uni-hamburg.de(sven.bettermann"AT"chemie.uni-hamburg.de), werner.pauer@uni-hamburg.de(pauer"AT"chemie.uni-hamburg.de)

Room: TMC A204 or B218

Tel.: 040 42838 -7220 oder -6007

Duration: 4-6 weeks

Designed for: Research internship in a Bachelor-/ Masterthesis, Promotion

General description:

Based on previous laboratory experiments on the reaction calorimeter RC1e, the applicability of 3D-printed stirring elements in a 10 L batch reactor shall be investigated within the scope of a bachelor thesis or a research internship. An already established reactor system is to be used for this purpose. The aim is to compare different 3D-printed stirring elements with regard to their mixing behaviour and their influence on the product properties of emulsions on a larger scale. The bachelor thesis and the research internship, respectively, provide an insight into scale-up operations, 3D printing as a new additive manufacturing process, emulsion polymerisation as well as various analysis methods for the reliable quantification of process targets.

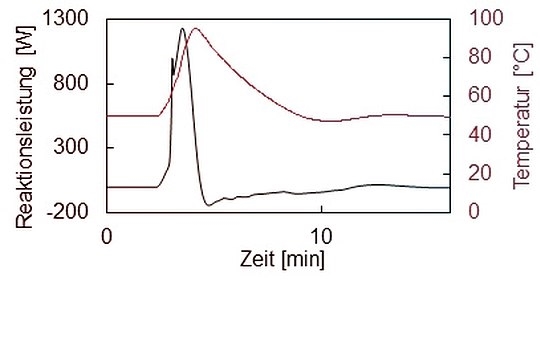

Calorimetric studies of miscellaneous initiators and initiator systems for the synthesis of polymers

Contact person: Werner Pauer

E-mail: werner.pauer@uni-hamburg.de(werner.pauer"AT"chemie.uni-hamburg.de)

Room: TMC B218

Phone: 040 42838 - 6007

Duration: 4-6 weeks

Interpretation: Research internship in a Bachelor-/ Masterthesis

General description:

Polyacrylates are to be synthesized within the scope of a bachelor thesis or research internship. For this purpose different initiators are used and their reaction behaviour is investigated by means of calometry. Additionally, the macromolecules synthesized in the reactor will be analyzed by HPLC, GPC and NMR.

The aim of this work is to compare the influence of the initiators on the final product and to optimize the reaction parameters in order to generate polymers in short reaction time and maximum conversion.

Topics covered: calorimetry; solvent polymerization; radical polymerization; reaction kinetics; reaction control; polymer analysis; data evaluation.

Acoustic levitation - investigation of multi-component mixtures in single drops

Contact person: Werner Pauer

E-mail: werner.pauer"AT"uni-hamburg.de

Room: TMC B218

Phone: 040 42838 - 6007

Duration: 4-6 weeks

Interpretation: Research internship or Bachelor- Masterthesis, Promotion

General description:

Mixtures of organic solvents and dispersions are to be examined with the aid of the acoustic levitator, which allows small solid or liquid samples to levitate without contact using a standing ultrasonic wave. This model system makes it possible to analyze a single drop and to track the physical and chemical processes taking place, such as evaporation, crystallization or reactions. Process parameters should be varied and their influence on the processes should be examined. Implemented online analytics should be applied in addition to inline Raman spectroscopy to gain a more detailed understanding of the processes.

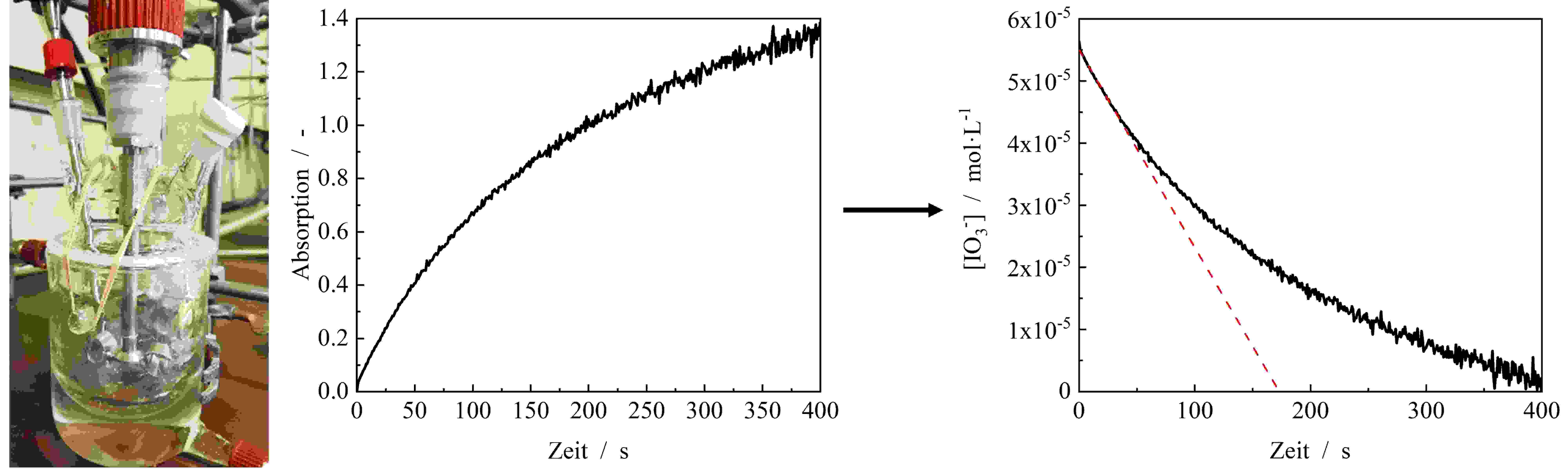

Determination of the temperature dependence of the Dushman reaction in highly viscous systems

Contact person: Werner Pauer

E-Mail: werner.pauer"AT"uni-hamburg.de

Room: B218

Tel.: 040 42838 -6007

Duration: 4-6 weeks

Designed for:Research internship in a Bachelor-/ Masterthesis, Promotion

General description:

The Villermaux-Dushman reaction is a very fast test reaction that is often used to characterize micromixing in different mixers. It consists of two partial reactions, an acid-base reaction and a comproportionation reaction, the so-called Dushman reaction. Knowledge of the kinetics of the Dushman reaction is of crucial importance to enable the understanding of the experimental data and the numerical calculation of micromixing times. Although it has been used in research and industry for over 20 years, the test reaction in highly viscous systems has hardly been researched to date. In particular, the temperature dependence of the reaction kinetics in highly viscous systems is an important factor that must be taken into account, as this changes both the viscosity of the solution and the reaction rate. The evaluation is time-resolved with the help of UV-Vis spectroscopy, the viscosity of the solutions is measured with a viscometer.

Functionalization of a 3d printed surface

Contact person:Werner Pauer

E-Mail: werner.pauer"AT"uni-hamburg.de

Room: TMC B218

Tel.: 040 42838 -6007

Duration: 4-6 weeks

Designed for:Research internship in a Bachelor-/ Masterthesis, Promotion

General description:

As part of this research work, a surface is first to be 3D printed in order to then functionalize it with a catalyst. Parameters such as time, temperature and concentration are to be examined. The functionalization should enable selective oxidation.

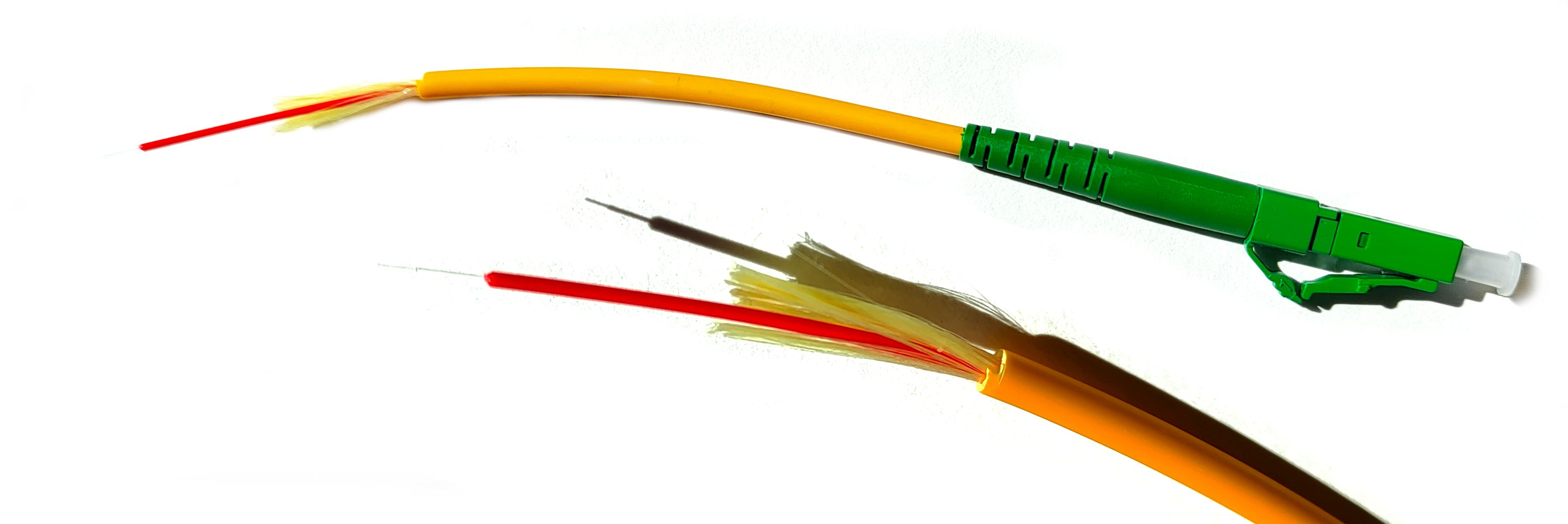

3D printed continuous reactors for emulsion polymerization and fiber optic temperature measurement

Contact person: Maria Klippert/Werner Pauer

E-Mail: maria.klippert"AT"uni-hamburg.de, , werner.pauer"AT"uni-hamburg.de

Room: TMC A204 or B218

Tel.: 040 42838 -7220 or -6007

Duration: 4-6 weeks

Designed for: Research internship in a Bachelor-/ Masterthesis

General description:

Continuous emulsion polymerizations are to be carried out in 3D-printed reactors with built-in glass fibers for fiber-optic temperature tracking in order to characterize the temperature profile along the reactor section and to determine heat transfer. By changing the heat transfer, it should be possible to predict the formation of deposits during the reaction. The fiber optic sensors should already be taken into account when modeling the components so that they can be integrated accordingly.

Investigation of the influence of macro and micro mixing quality on the propoxylation of polypropylene glycol using DMC catalysis in a loop reactor

Contact person: Andres Castro Villavicencio/Werner Pauer

E-Mail: andres.castro@uni-hamburg.de(wladislaw.dolshanskiy"AT"uni-hamburg.de) , werner.pauer"AT"uni-hamburg.de

Room: TMC C224 or B218

Tel.: 040 42838 -6054 oder -6007

Duration: 4-6 weeks

Designed for: Research internship in a Bachelor-/ Masterthesis, Promotion

- Investigate macromixing at the loop reactor

o Design and printing of clear Kenics mixing elements in the loop reactor

o Catalyst in PPG with PIV and dye injection with PLIF (RT)

- Micromixing on the 2L autoclave reactor

o VD response for micromix quality at injection point (RT) at different viscosities and different flow rates on the 2L autoclave reactor

o Comparison of two injection methods

o Residence time measurement with impact marking

- Reaction at the 2L autoclave reactor with knowledge gained from different injections

Propoxylation of Polypropylene Glycol (PPG) is an important process in the manufacture of polyurethanes, lubricants and other chemicals. The use of double metal cyanide (DMC) catalysts in a loop reactor enables efficient and cost-effective production of PPG. The mixing quality is an important factor for the effectiveness and efficiency of the process and the final product properties. Macro and micro mixing quality can be influenced by various methods, e.g. by using Kenics mixing elements or by varying flow rates and injection methods.

The aim of this project is to investigate the influence of macro and micro mixing quality on the propoxylation of PPG by DMC catalysis in a loop reactor. By systematically varying the mixing conditions, optimal conditions for an efficient and cost-effective production of PPG are to be determined. The loop reactor will be equipped with a mixer, which will be manufactured using the mSLA 3D printing process and made completely transparent so that Particle Image Velocimetry (PIV) and Planar Laser Induced Fluorescence (PLIF) can be used inside.

The project comprises two sub-areas: macro-mixing on the 3D printed loop reactor and micro-mixing on the 2L stainless steel autoclave reactor using the Villermaux-Dushman reaction. In both sub-areas, the mixing conditions are varied systematically, e.g. by using Kenics mixing elements, varying flow rates and injection methods. PIV and PLIF are used to analyze the mixing quality in the loop reactor. The mixer in the loop reactor is made using the mSLA 3D printing process and made completely transparent so that you can work with PIV and PLIF inside.

Summary: This project aims to investigate the influence of macro and micro mixing quality on the propoxylation of PPG by DMC catalysis in a loop reactor. By systematically varying the mixing conditions, optimal conditions for an efficient and cost-effective production of PPG are to be determined. The use of a mSLA 3D printed transparent mixer enables real-time visualization and analysis of the mixing dynamics, thus contributing to a deeper understanding of the mixing conditions and process optimization.

Investigation of synthesis processes for the production of silane-modified polymers

Contact person: Werner Pauer

E-Mail: werner.pauer"AT"uni-hamburg.de

Room: TMC B218

Tel.: 040 42838 -6007

Duration: 4-6 weeks

Designed for: Research internship in a Bachelor-/ Masterthesis

General description:

Thanks to their unique properties, polyurethanes make a decisive contribution to a high quality of life and are among the

economically most important specialty plastics. However, the isocyanate-containing components in polyurethane systems, which are extremely hazardous to health, are subject to increasingly strict legal restrictions. An isocyanate-free alternative based on polyurethane prepolymers are silane-modified polymers.

First, these polymers are to be produced and characterized in a batch process. The aim of the work is to develop new synthesis processes and to transfer the discontinuous procedure to a continuous procedure.

Sustainable Polyester

Contact person: Anne Frankowski, Dr. Werner Pauer

E-Mail: anne.frankowski"AT"uni-hamburg.de, werner.pauer"AT"uni-hamburg.de

Room: TMC C224 or B218

Tel.: 040 42838 -6054 oder -6007

Duration: 4-6 weeks

Designed for: Research internship in a Bachelor-/ Masterthesis/ Promotion

Polyesters account for approximately 18 % of the polymers produced worldwide each year, finding broad application particularly in textile fibers and food packaging (e.g., polyethylene terephthalate, PET). To date, most polyesters are derived from fossil resources, contributing to high CO₂ emissions and other environmental concerns. To create more sustainable alternatives, we are focusing on the development of bio-based polyesters. For this bio-based monomers obtained from renewable resources such as food waste, biomass, or even carbon dioxide. The production of these monomers enables both existing and innovative polycondensation processes to be adapted, allowing for tailor-made sustainable polyesters. The goal is to develop bio-based polyesters that are comparable or even superior to their fossil-based counterparts in terms of analytical and mechanical properties, while also opening up new fields of application.

Continuous emulsion polymerization

Contact person: Dr. Werner Pauer

e-mail: werner.pauer@uni-hamburg.de(pauer"AT"chemie.uni-hamburg.de)

Room: TMC B218

Phone: +49 40 42838-6007

Duration: 6 months

Designed for: Research internship in a Bachelor-/ Masterthesis, Promotion

Focus: Plant design, construction and operation, analysis, statistical evaluation and modelling