Optimization of chemical reactions using microreaction technology

Micro process engineering: Safety characteristics of strongly exothermic reactions

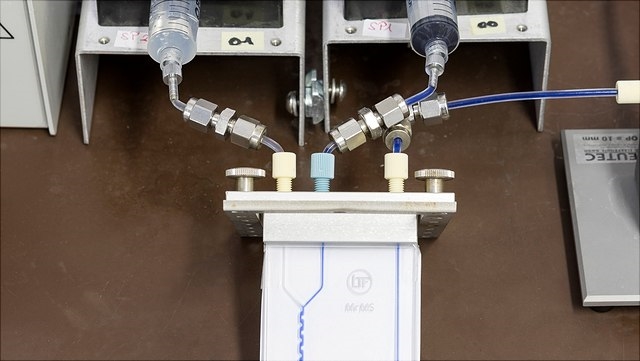

Micro process engineering deals with the realization of process engineering processes in plants whose effective dimensions are in the micrometer range. This technology opens new ways for the development of chemical processes and the construction of economical production plants. It is known from numerous experiments that very small reaction spaces have many advantages in chemistry. For example, they naturally have an extremely good surface-to-volume ratio and are, therefore, very good at transporting heat. The small reaction chambers, thus, offer a high degree of safety in exothermic reactions and explosive reaction mixtures. This also allows higher selectivities and yields to be achieved under safe operating conditions than in conventional macroscopic devices. Further advantages of continuous operation in microstructures are narrow residence time distributions and low system inertia for an efficient process control. Although micro-reactors do not open up new chemistry, they can improve processes and also make them more economical. However, microstructure technology does not necessarily mean that everything is small. A pilot reactor on an industrial scale measures 1.4 meters in diameter and is about 4 meters high. Its weight is around 9 tons. It is only inside that it becomes small. The reactions take place in modular microstructured units.