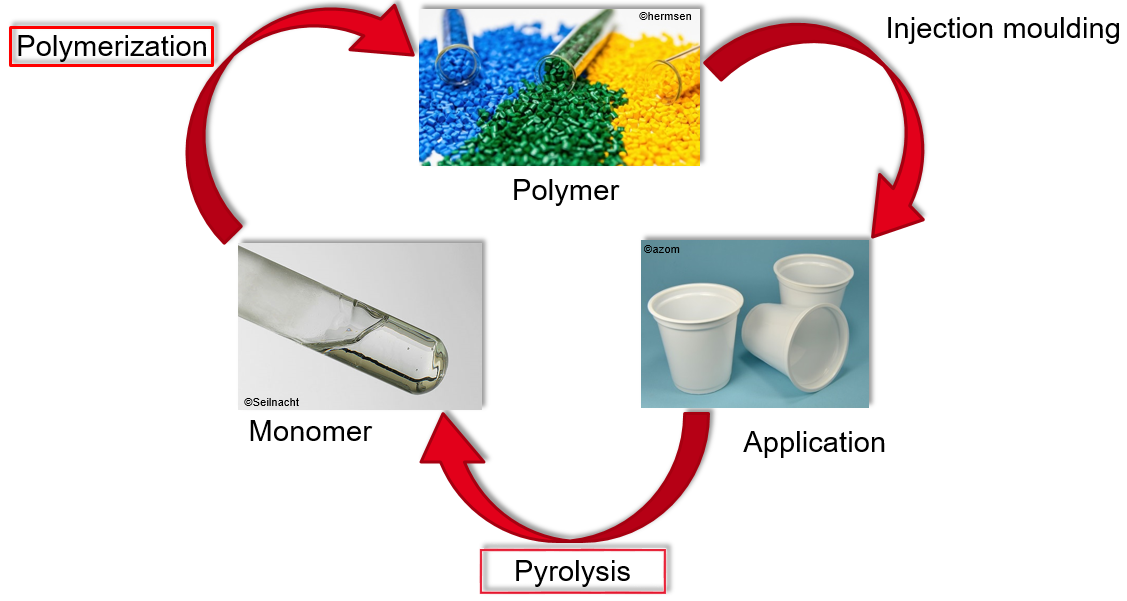

The issue of plastic recycling has recently attracted attention in the media. The established process of material recycling is reaching its limits due to the presence of various additives and the phenomenon of downcycling. One alternative is chemical recycling, especially pyrolysis. During pyrolysis, the plastic is heated to temperatures in the range of 400 – 800 °C under oxygen exclusion. This results in homolytic cleavage of the C-C bonds. Certain plastics, such as polystyrene (PS), can be converted back into the corresponding monomers.

During my doctorate, I focus my research on the pyrolysis of different plastics and waste fractions, especially PS. Therefore, chemical and procedural aspects are analysed on a continuous pilot scale plant with a capacity of 1 kg/h to ensure high monomer recovery.